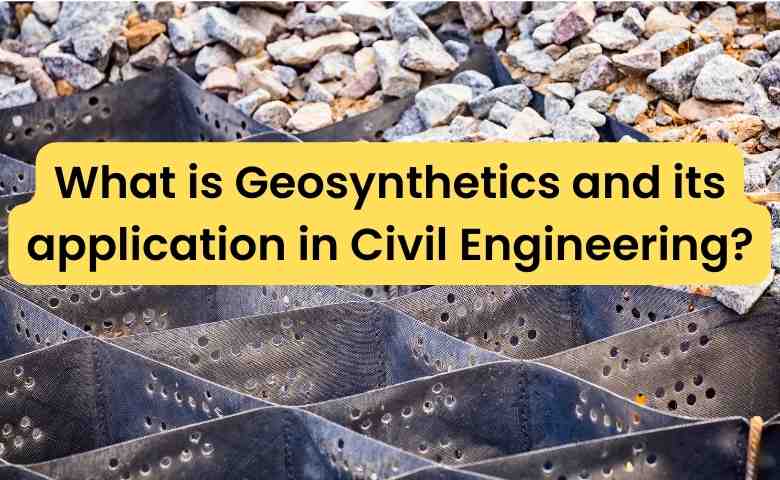

In the construction industry, the role of geogrids—synthetic materials designed to reinforce soil and aggregate—has become increasingly critical. These seemingly simple materials are pivotal in enhancing the stability and performance of various infrastructure projects. Top Geogrid manufacturer are at the forefront of driving innovation, developing advanced solutions that are transforming construction practices. This article explores how leading geogrid manufacturers are shaping the future of construction through technological advancements and innovative approaches.

The Essential Role of Geogrids in Construction

Geogrids are crucial for stabilizing soil and improving load distribution in various engineering applications. They are typically used in road construction, retaining walls, embankments, and erosion control. By reinforcing the soil, geogrids reduce deformation, increase load-bearing capacity, and enhance the overall stability of structures.

Key Innovations from Leading Geogrid Manufacturers

1. Development of High-Performance Materials

One of the most significant advancements in geogrid technology is the development of high-performance materials. Modern geogrids are made from advanced polymers and composites that offer superior strength and durability. Materials such as high-density polyethylene (HDPE), polyester, and fiberglass are now commonly used to manufacture geogrids.

Innovation Highlight: GeoTech Innovations, a leading geogrid manufacturer, has developed a new line of geogrids using a blend of high-strength polymers and composite materials. These geogrids provide exceptional tensile strength and resistance to environmental factors, making them suitable for demanding applications in harsh conditions.

2. Advanced Design Configurations

Geogrid design has evolved to include advanced configurations that improve performance. Innovations such as biaxial and triaxial geogrids provide reinforcement in multiple directions, enhancing load distribution and stability. The optimization of mesh patterns and aperture sizes has also contributed to more effective soil reinforcement.

Innovation Highlight: GeoGrid Solutions has introduced a range of geogrids with optimized mesh patterns and aperture sizes. Their biaxial and triaxial designs offer improved load distribution and resistance to deformation, making them ideal for high-traffic areas and challenging soil conditions.

3. Sustainable and Eco-Friendly Practices

Sustainability is a growing focus in the construction industry, and geogrid manufacturers are responding with eco-friendly solutions. Many companies are producing geogrids from recycled materials, such as post-consumer plastics, and exploring biodegradable polymers to reduce environmental impact.

Innovation Highlight: EcoGeoTech has pioneered the development of geogrids made from recycled plastics and biodegradable polymers. Their commitment to sustainability not only reduces the environmental footprint of geogrid production but also supports more eco-friendly construction practices.

4. Integration of Smart Technologies

The integration of smart technologies into geogrid systems represents a significant leap forward. Modern geogrids can be equipped with sensors and monitoring devices that provide real-time data on soil conditions, load distribution, and structural performance. This technology enables engineers to make informed decisions about maintenance and repairs.

Innovation Highlight: SmartGeo Systems has developed geogrids with embedded sensors that monitor soil conditions and structural performance. This real-time data allows for proactive maintenance and optimization of infrastructure, leading to enhanced durability and safety.

5. Enhanced Installation Techniques

Innovations in installation techniques are improving the efficiency and accuracy of geogrid placement. Advanced machinery and automated systems are making it easier to install geogrids in challenging environments, while comprehensive training and support services ensure proper installation.

Innovation Highlight: Precision GeoTech has introduced new machinery and automated systems for geogrid installation. Their technology reduces labor costs and ensures precise placement, maximizing the performance and longevity of geogrids.

Real-World Applications and Success Stories

Case Study 1: Urban Roadway Reinforcement

An urban roadway project utilized advanced geogrids to address soil instability and high traffic loads. The use of high-strength composite geogrids resulted in improved load distribution and reduced pavement deformation. The project demonstrated the effectiveness of modern geogrid technology in enhancing road performance and longevity.

Outcome: The urban roadway experienced reduced maintenance needs and extended lifespan, showcasing the benefits of advanced geogrid materials and designs.

Case Study 2: Embankment Stabilization

In a large-scale embankment stabilization project, the integration of smart geogrids with embedded sensors provided real-time data on soil conditions and load distribution. This information enabled engineers to make timely adjustments and optimize the embankment’s performance.

Outcome: The embankment achieved enhanced stability and safety, highlighting the advantages of incorporating smart technologies into geogrid systems.

The Future of Geogrid Technology

The future of geogrid technology is bright, with ongoing advancements in materials, design, and smart technologies. Future developments may include further improvements in material strength, the integration of artificial intelligence for real-time performance optimization, and expanded eco-friendly solutions.

Industry Insight: Dr. Emily Johnson, Chief Innovation Officer at GeoTech Innovations, envisions a future where geogrid technology continues to evolve: “As we explore new materials and technologies, the possibilities for geogrids are vast. We anticipate even greater advancements in performance and sustainability, driving progress in infrastructure development and construction practices.”

Conclusion

Leading geogrid manufacturers are at the forefront of driving innovation in the construction industry. Through advancements in materials, design configurations, sustainability practices, and smart technologies, these manufacturers are shaping the future of infrastructure. By understanding the key innovations and success stories, we gain insight into the crucial role of geogrids in reinforcing tomorrow’s roads and structures. As technology continues to advance, geogrid manufacturers will remain essential in delivering robust, sustainable, and high-performing infrastructure solutions.