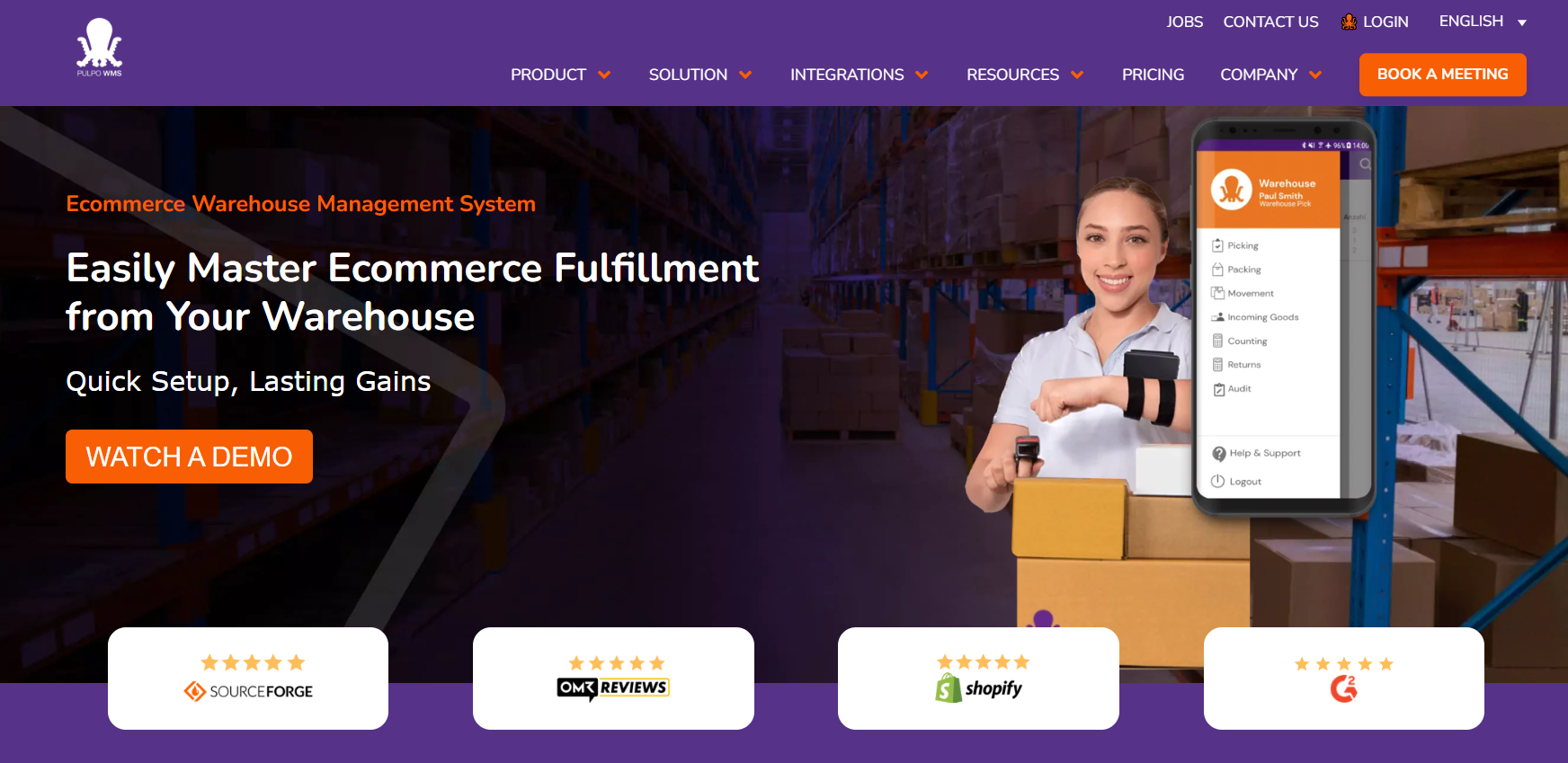

In the dynamic world of logistics and supply chain management, efficiency and accuracy are paramount. Companies are increasingly turning to third-party logistics (3PL) providers to streamline their operations, reduce costs, and enhance customer satisfaction. Central to this transformation is the 3PL warehouse management system (WMS), a critical tool that integrates technology with logistics to optimize warehouse operations. This article explores how a 3pl warehouse management system can optimize logistics, highlighting its key benefits and features.

Understanding 3PL Warehouse Management Systems

A 3PL warehouse management system (WMS) is a specialized software solution designed to manage and optimize the operations of third-party logistics providers. These systems are tailored to handle the complexities of warehousing and logistics on behalf of multiple clients. They integrate with various business applications to streamline processes, improve accuracy, and enhance overall efficiency.

Key Features of 3PL Warehouse Management Systems

To understand how a 3PL WMS optimizes logistics, it is essential to explore its key features:

1. Real-Time Inventory Tracking

Real-time inventory tracking is a fundamental feature of 3PL WMS. It provides up-to-date information on inventory levels, locations, and movements within the warehouse.

Benefits:

- Accurate Stock Levels: Ensures that inventory levels are current, reducing the risk of stockouts and overstocking.

- Improved Visibility: Provides clients with real-time access to inventory data, enhancing transparency and communication.

- Reduced Errors: Minimizes discrepancies between physical inventory and system records.

2. Order Management and Fulfillment

Order management and fulfillment capabilities are central to a 3PL WMS. The system handles order processing, picking, packing, and shipping, ensuring that orders are fulfilled accurately and efficiently.

Benefits:

- Automated Order Processing: Streamlines order processing with automated workflows, reducing manual effort and processing time.

- Efficient Picking and Packing: Utilizes optimized picking routes and packing instructions to speed up the fulfillment process.

- Order Accuracy: Reduces the risk of errors through barcode scanning and real-time verification.

3. Integration with Other Systems

A 3PL WMS integrates with various business applications, including enterprise resource planning (ERP) systems, customer relationship management (CRM) systems, and ecommerce platforms.

Benefits:

- Seamless Data Flow: Ensures smooth data exchange between different systems, improving accuracy and reducing duplication.

- Enhanced Collaboration: Facilitates better communication and coordination between the 3PL provider, clients, and other stakeholders.

- Comprehensive Reporting: Provides integrated reporting and analytics for better decision-making.

4. Warehouse Layout Optimization

Warehouse layout optimization features help design and manage warehouse layouts to maximize space utilization and improve operational efficiency.

Benefits:

- Efficient Space Utilization: Optimizes storage locations and shelving arrangements to make the best use of available space.

- Reduced Travel Time: Minimizes the distance staff need to travel within the warehouse, speeding up picking and packing processes.

- Improved Workflow: Enhances the overall workflow by organizing products and materials in a logical and accessible manner.

5. Real-Time Reporting and Analytics

Real-time reporting and analytics provide insights into warehouse operations, performance metrics, and key performance indicators (KPIs).

Benefits:

- Performance Monitoring: Tracks key metrics such as order fulfillment rates, inventory turnover, and warehouse productivity.

- Data-Driven Decisions: Provides actionable insights that help optimize operations and identify areas for improvement.

- Trend Analysis: Analyzes trends and patterns to forecast demand, plan resources, and make informed strategic decisions.

6. Advanced Security Features

Advanced security features ensure the safety and integrity of warehouse operations and data.

Benefits:

- Data Security: Protects sensitive information with encryption and access controls.

- Operational Security: Monitors warehouse activities to prevent theft, loss, and unauthorized access.

- Compliance: Ensures compliance with industry regulations and standards.

Benefits of Implementing a 3PL Warehouse Management System

Implementing a 3PL warehouse management system offers numerous benefits that can significantly enhance logistics operations. Here are some of the key advantages:

1. Enhanced Operational Efficiency

A 3PL WMS optimizes various aspects of warehouse operations, leading to increased efficiency and productivity.

How It Enhances Efficiency:

- Automated Processes: Automates repetitive tasks such as order processing and inventory tracking, reducing manual effort and errors.

- Optimized Workflows: Streamlines workflows and operations, leading to faster order fulfillment and reduced lead times.

- Resource Management: Efficiently manages resources, including labor and equipment, to maximize productivity.

2. Improved Accuracy and Reduced Errors

Accuracy is critical in warehouse operations, and a 3PL WMS helps minimize errors through various features and technologies.

How It Improves Accuracy:

- Barcode Scanning: Uses barcode scanning to ensure accurate item selection and verification.

- Real-Time Updates: Provides up-to-date information on inventory and order status, reducing discrepancies.

- Automated Checks: Includes automated validation and quality checks to catch errors before they impact order fulfillment.

3. Cost Savings

A 3PL WMS can lead to significant cost savings by improving operational efficiency and reducing errors.

How It Saves Costs:

- Reduced Labor Costs: Automates tasks and optimizes workflows, reducing the need for manual labor.

- Lower Inventory Costs: Improves inventory management, reducing the risk of stockouts and overstocking.

- Minimized Returns: Enhances order accuracy, reducing the number of returns and associated costs.

4. Enhanced Customer Satisfaction

Customer satisfaction is a key factor in the success of any logistics operation. A 3PL WMS contributes to higher customer satisfaction through timely and accurate order fulfillment.

How It Enhances Satisfaction:

- Fast Fulfillment: Speeds up the order fulfillment process, leading to quicker delivery times.

- Order Accuracy: Ensures that orders are fulfilled correctly, reducing the likelihood of errors and returns.

- Real-Time Tracking: Provides customers with real-time visibility into their orders, enhancing transparency and communication.

5. Scalability and Flexibility

A 3PL WMS offers scalability and flexibility to accommodate the growing and changing needs of businesses.

How It Supports Scalability:

- Adaptable Solutions: Can be tailored to meet the specific requirements of different clients and industries.

- Scalable Architecture: Supports growth by accommodating increasing order volumes and expanding warehouse operations.

- Flexible Integration: Integrates with various business systems and platforms, allowing for seamless expansion and adaptation.

Key Considerations When Choosing a 3PL Warehouse Management System

Selecting the right 3PL warehouse management system requires careful consideration of several factors to ensure that the solution meets your specific needs. Here are some key considerations:

1. Integration Capabilities

Ensure that the 3PL WMS integrates seamlessly with your existing business systems, such as ERP, CRM, and ecommerce platforms. This integration is crucial for ensuring smooth data flow and enhancing overall efficiency.

2. Feature Set

Evaluate the features offered by the 3PL WMS and determine whether they align with your operational requirements. Key features to consider include real-time inventory tracking, order management, warehouse layout optimization, and reporting capabilities.

3. User-Friendliness

The software should have an intuitive interface that is easy for warehouse staff to use. A user-friendly system reduces the need for extensive training and helps minimize errors.

4. Scalability and Flexibility

Choose a solution that can scale with your business and adapt to changing needs. The WMS should support growth and accommodate varying order volumes and warehouse configurations.

5. Cost and ROI

Consider the cost of the 3PL WMS and evaluate its return on investment. While there may be an upfront investment, the benefits of improved efficiency, accuracy, and customer satisfaction can lead to significant long-term savings.

6. Support and Training

Ensure that the software provider offers adequate support and training resources. Access to customer support and training materials will help your team effectively use the software and address any issues that arise.

Conclusion

A 3PL warehouse management system is a powerful tool for optimizing logistics and enhancing order fulfillment. By integrating advanced technologies and automating key processes, a 3PL WMS improves efficiency, accuracy, and overall performance. Key features such as real-time inventory tracking, automated order management, and optimized picking routes contribute to its effectiveness.

Implementing a 3PL WMS offers numerous benefits, including enhanced operational efficiency, improved accuracy, cost savings, and higher customer satisfaction. As businesses continue to navigate the complexities of logistics and supply chain management, leveraging the capabilities of a 3PL warehouse management system will be essential for staying competitive and achieving operational excellence.

When choosing a 3PL WMS, consider factors such as integration capabilities, feature set, user-friendliness, scalability, and cost. By selecting the right solution and leveraging its capabilities, businesses can transform their logistics operations, optimize warehouse performance, and drive long-term success.