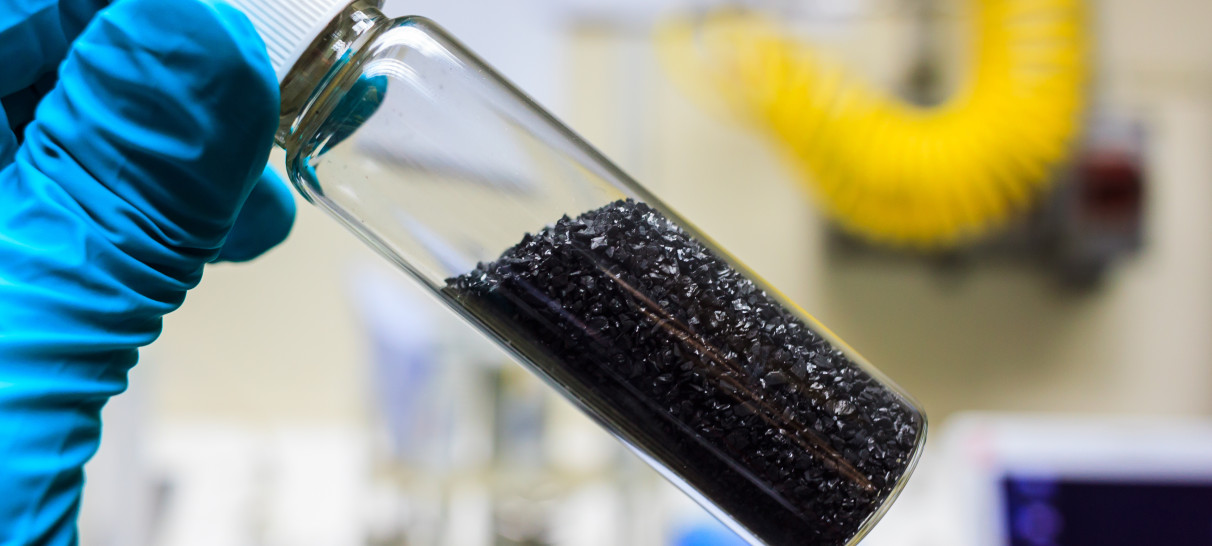

Today’s industry strongly demands lightweight and durable materials, particularly in aerospace, automotive, and building construction. It has resulted in remarkable progress in both carbon black composites and a feedstock with particularly carbon black composites exhibiting great architecture. Carbon black composites are materials developed by mixing carbon black with other substances such as plastic or resin, which leads to a product that is until strong and resilient. Raw carbon black feedstock is the basic material used for manufacturing carbon black and is the main component of many composites. Moreover, carbon fibre plastic has been in vogue because of its remarkable strength/weight ratio and wide utilization domains. This article will delve into recent advances in these fields, unveiling state-of-the-art technologies and applications which are redefining the course of material science.

Developments in Carbon Black Composites

Carbon black composites are viewed with particular interest because they have several unique features, including high strength, good electrical conductivity and good resistance to harsh environments. They find their applications in the most different areas – for instance, in the manufacturing of car parts, the development of aircraft components, and production of the electrical shielding materials.

- Graphene-Enhanced Carbon Black Composites

It is suggested to use graphene in the structure of carbon black composites to gain some extra mechanical and electric features. Graphene, a flattened structure of carbon atoms that are arranged in a hexagonal pattern, is a very strong nanomaterial due to its superior strength-to-weight ratio and can conduct electricity. Additionally, scientists have innovated by adding graphene to carbon black composites, resulting in materials with more tensile strength, better heat and electricity conductivity, and also high barrier ability.

- Self-Healing Carbon Black Composites

Self-healing capabilities in carbon composites are a great advancement. According to these composites, there are some additives or microcapsules which can automatically repair cracks or damages at the initial stage. Besides increasing the durability and lifespan of the composite, this feature also reduces maintenance expenses and provides a greater level of safety, especially in critical applications.

- Carbon Black Nanocomposites

Nanomaterials were integrated with carbon nanotubes and nanofiber with carbon black dark to create carbon black nanocomposites. Such high-end materials, which are referred to as advanced composites, have unmatched mechanical, thermal, and electrical characteristics in comparison to the old carbon black composites. Nanocomposites are among the most attractive technologically advanced materials, especially for electronics, energy storage, and aerospace due to their lightweight and high performance.

Carbon Black Sources Innovations

The manufacture of superior carbon black feedstocks is central to the production of high-quality carbon black composites and other carbon-made materials. The researchers are looking for new ways of getting feedstock to be qualitatively and environmentally more improved.

- Biomass-Derived Carbon Black Feedstock

Conventional carbon black, which is the main feedstock, is derived from fossil fuels, namely petroleum or coal, thus arousing green issues to tackle this challenge, scientists are looking at biomass for a more planet-friendly carbon black, such as agricultural waste, wood pieces or dedicated for energy plantation biomass as a potential feedstock. This method not only cuts down the environmental impact but also advances the circular economy by reusing renewable resources.

- Plasma-assisted Carbon Black Feedstock Production

Plasma technology offers an innovative approach to the production of carbon black feedstock. This technique consists of heating the carbon source at high pressures and temperatures in the plasma reactor where a tiny element of uniform carbon black particles is produced. Plasma-assisted processes have three primary advantages, such as improved control over particle size and distribution, better product quality, and more energy savings.

- Carbon Capture and Utilization for Carbon Black as a Feedstock

The carbon capture and utilization (CCU) technologies have been increasingly recognized as one tool to keep the carbon dioxide off the air while they are also creating value from the waste carbon dioxide. The analysts are looking into the fastness of recycling the diluted CO2 for carbon black and other carbon-containing matter. This strategy not only comes with environmental protection, green industry and business opportunities but also expands the carbon-based market.

Advances in Carbon fiber Plastic

Carbon fiber plastic, also known as carbon fiber reinforced polymer (CFRP), is working like a revolutionary medium in many industries which is because of its fantastic strength-to-weight ratio and extreme durability. Through constant research and development, the processing methods and applications only have become more advanced.

- 3D Printed Carbon fiber plastics

3D printing, also referred to as additive manufacturing, has been a breakthrough technology that dramatically enhances our ability to produce intricate structures and components. The arrival of the three-dimensional printing technology for carbon fiber keeps pace with the same and adds to the lightweight and performance parts used in the industries such as aerospace, automotive and sports equipment. This tech helps in the production of complex shapes & designs which were difficult or impossible to develop using traditional production methods.

- Hybrid Carbon Fiber Plastic Composites

In addition, the researchers are actively pursuing the combination of other materials with carbon fiber plastic and they are looking into using ceramics, metals or nanoparticles to make hybrid composites. These mixed materials merge the strong points of different materials into a new material which has better mechanical, thermal, and electrical outputs customized for particular uses. For instance, metal-carbon fiber composite materials increase rigidity and strength while ceramic-carbon fiber composite materials improve thermal and chemical resistance.

- Recycling and reuse of carbon fiber plastic.

Along with the growing demand for carbon fiber plastic, dealing with the problem of residues and what happens with the waste after the end of life has become a priority. Researchers are finding ways of reusing and recycling carbon fiber plastic components with different methods including mechanical recycling, thermal recycling and solvent-based recycling. These attempts not only lead the way to sustainability but also help reduce costs and conservation of resources.

Conclusion

Carbon black composites, carbon black feedstock, and carbon fiber plastic fields are developing very fast as manufacturers are continuously looking for better options. These developments have a huge potential for improving lots of industries from the development of aircraft, machines, and vehicles to building and electronics. With explorations ongoing on new materials, production methods, and applications, we are of high probability to observe more impressive development in the not-too-distant future. These advancements are not only meant to create new goods but also play a vital role in environmental protection by encouraging ecological improvements and resource efficiency. The future of material science is promising and it is these three materials that will make a tremendous impact in shaping the world we inhabit.