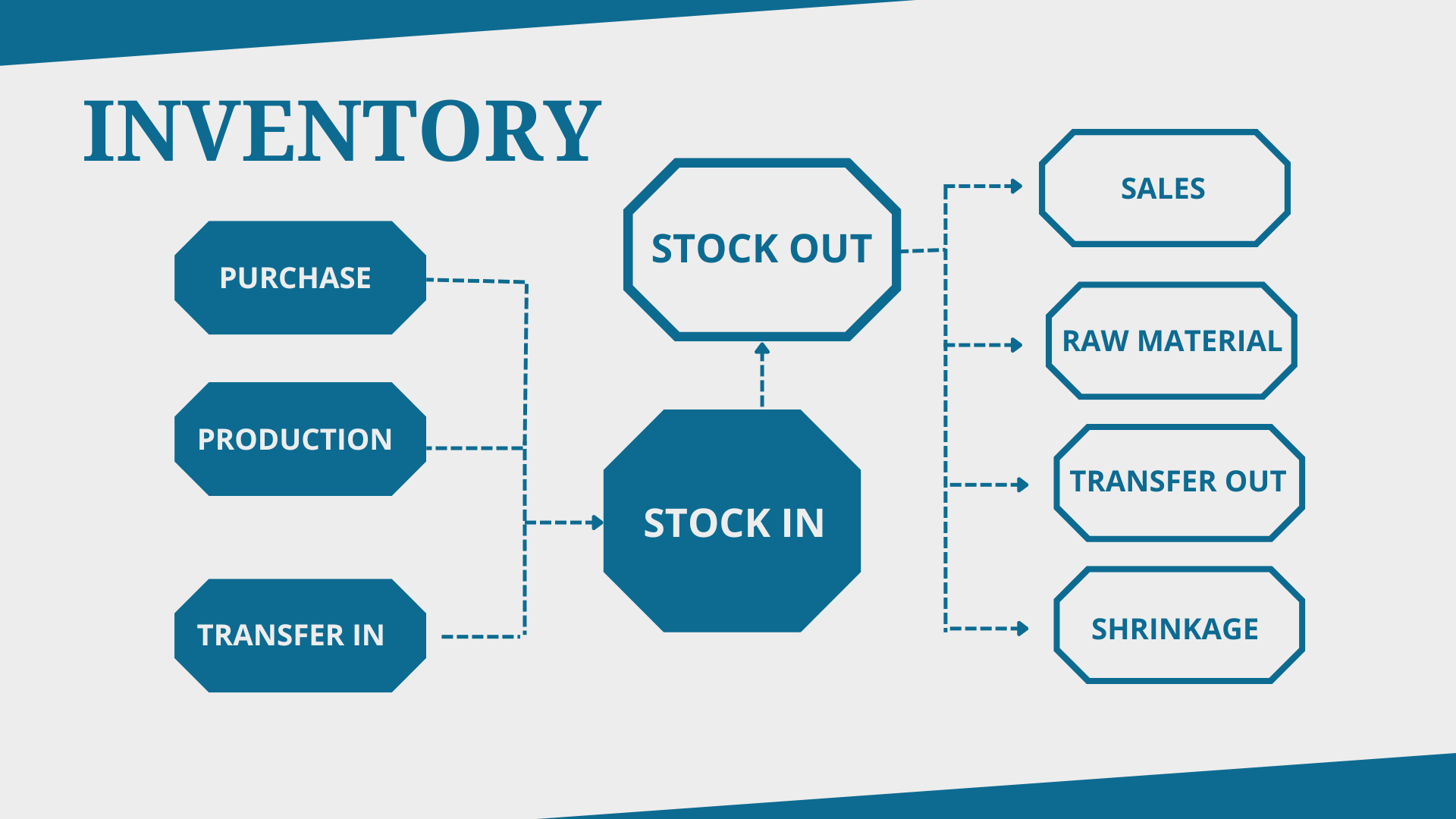

Inventory Fluctuations: Stock outs and overstocking are perhaps some of the most faced problems by companies across the globe across industries affecting the business operations, their balance sheets and more critically the consumers. No business is immune to variables such as fluctuations in customer demand and supply, among others, and, thus, how such changes are dealt with in relation to inventory could significantly affect the competitiveness and the overall profitability of the business. To carry out our goal, we will discuss techniques that organizations can use to overcome these fluctuations successfully and maintain ideal inventories, thus running efficient operations.

Agile Supply Chain Management:

An agile supply chain is pivotal for managing fluctuating inventory levels, as supply chain dynamics follow. These points make it ideal for businesses to closely work with suppliers, manufacturers, and distributors since it enables them to easily change supply and demand. Businesses can also leverage advanced technology such as bookkeeping software to ensure seamless tracking and management of financial transactions amidst dynamic market conditions. Furthermore, the networks of supplier and operating some buffer inventory for some key components or material are possible to make less risky the supply chain and ensure the continuity of operations.

Accurate Demand Forecasting:

Through analysis of previous sales, market analysis, and other relevant information, one can estimate the future market demand more effectively all as an important aspect of modern management. Recent technological innovations in forecasting strategies like predictive analytics with machine learning can make it possible for the businesses to forecast variations in the market and consequently adapt the inventory. The avoidance of overstocking or stockout therefore implies that through embracing the consumer behavior analysis and the market trends, it becomes possible for businesses to manage their inventory in the most efficient manner.

Inventory Optimization Techniques:

The best methods of inventory management can assist a firm in achieving the best balance between the costs of storing inventory and the periodic availability of those stock. Two variables determine demand uncertainty – risk and variability, while for inventory, it is the value that drives classification of inventory items. One of these is the application of JIT inventory management and EOQ that help companies in minimizing unnecessary inventory stock but at the same time are able to facilitate timely acquisition of stocks. Additionally, the use of inventory system that involves forecasting enables organizations to increase control of inventory restocking as well as enhancing the working inventories turnover rates.

Flexible Production Planning:

Scheduling is one of the critical aspects of production since companies can sometimes experience a change in demand ratios, and as a result, experience large stocks of unsold or slow-moving goods. The use of lean manufacturing and concept of Agile Manufacturing and production helps companies maintain the pace of production as per the changing demand in the market. Through multi-skilling of the employees and having cross-trained multiple-product manufacturing teams, the flexibility of production capacity is increased which in turn enables the business to spread its resources in response to the change in need of its products.

Collaborative Partnerships and Alliances:

Inventory volatility poses a threat to today’s businesses, and building cooperation with essential stakeholders may address this factor. Working with the retailers, distributors, and logistics providers to make available the information and tools ensures the business has improved supply chain transparency and timely response. By using vendor-managed inventory programs and consignment arrangements, vendors and customers can coordinate their work; this approach makes it possible to trim inventory carrying costs and avoid stock-outs.

To sum up, inventory management is a very important factor that helps companies determine how effectively they can manage their inventory and not cease to be profitable when faced with volatility. Dynamic planning and analysis, methodologies of fast and flexible supply chain management, and inventory management solutions can contribute to improvement of the enterprise’s performance in regard to the reaction on the positive or negative changes. Furthermore, the development or formation of key long-term business relations and strategic partnerships creates opportunities to manage supply chain risks and equitably leverage on upcoming opportunities.